Tesla-approved adhesives are vital for safe and effective repairs of electric vehicle battery compartments, ensuring structural integrity, compatibility with specific vehicle requirements, and optimal battery security. Using these specialized bonding solutions, which meet Tesla's stringent standards, is crucial to maintain the reliability and longevity of Tesla vehicles, addressing unique challenges like tight battery packing and rigorous demands. Correct application following manufacturer guidelines fosters a robust bond, providing dependable bodywork for both performance and safety.

Tesla vehicles are renowned for their cutting-edge technology, including advanced battery systems. When repairs or replacements are needed within the battery compartment, using the right Tesla-approved adhesives is critical. This ensures structural integrity, safety, and optimal performance. This article delves into understanding Tesla’s strict battery compartment requirements, highlights why approved adhesives matter, and provides guidance on selecting and applying the best adhesive for long-lasting results.

- Understanding Tesla's Battery Compartment Requirements

- Why Tesla-Approved Adhesives Matter for Repairs

- Selecting and Applying the Right Adhesive for Optimal Performance

Understanding Tesla's Battery Compartment Requirements

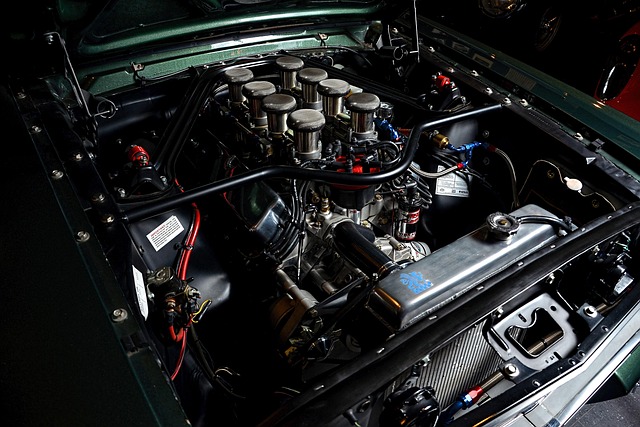

Tesla’s battery compartments are intricate systems designed to house and protect high-voltage batteries crucial for their electric vehicles’ performance and safety. When repairs or replacements are required, adhering to Tesla’s specific guidelines is essential. The company mandates the use of Tesla-approved adhesives to ensure structural integrity and prevent any potential hazards associated with electrical components. These adhesives play a critical role in securing battery compartment parts, from panels to connectors, maintaining the vehicle’s overall efficiency and safety standards.

Using the wrong adhesive or failing to follow recommended installation procedures can compromise the integrity of the repair. This is particularly important for collision centers or individuals undertaking dent removal or other body work, as it directly impacts the longevity and reliability of Tesla vehicles. Therefore, prioritizing Tesla-approved adhesives is a key step in achieving high-quality vehicle repair outcomes.

Why Tesla-Approved Adhesives Matter for Repairs

Tesla-approved adhesives play a pivotal role in ensuring the structural integrity and safety of electric vehicles. These specialized bonding solutions are designed to meet Tesla’s stringent standards, which is why they’re critical for any repair or restoration work on their batteries and vehicle compartments. When it comes to car body restoration or vehicle bodywork repairs, using the right adhesive is more than just a matter of aesthetics; it guarantees the longevity and reliability of the electric drive train.

The need for Tesla-approved adhesives arises from the unique challenges posed by electric vehicles (EVs). Unlike their internal combustion engine counterparts, EVs have high-voltage batteries packed tightly within their frames. Any repair or replacement work must not only be precise but also secure, as even minor issues with bonding could lead to serious safety hazards and compromised vehicle performance. With Tesla’s approval, these adhesives ensure a robust bond that can withstand the rigorous demands of EV ownership while offering peace of mind for drivers.

Selecting and Applying the Right Adhesive for Optimal Performance

When repairing a Tesla’s battery compartment, choosing the correct adhesive is paramount for long-lasting performance and safety. Opting for Tesla-approved adhesives ensures compatibility with specific vehicle requirements, guaranteeing both structural integrity and optimal battery security. These specialized adhesives are designed to withstand high temperatures, resist corrosion, and maintain flexibility over time, all critical factors in a vehicle’s bustling electrical system.

Selecting the right adhesive involves understanding your car damage repair needs. Consider factors like the type of surface, environmental conditions, and expected load or stress. For instance, a collision repair might require an adhesive with superior impact resistance, while routine bodywork repairs may need one that offers seamless bonding in moist environments. Applying these Tesla-approved adhesives correctly is equally vital; following manufacturer guidelines ensures precise application, fostering a robust bond for dependable vehicle bodywork.

When repairing a Tesla battery compartment, using Tesla-approved adhesives is paramount. These specialized adhesives meet stringent performance criteria, ensuring structural integrity and long-lasting reliability in these critical areas. By selecting the right adhesive and applying it correctly, you can achieve optimal results, maintaining the safety and efficiency of Tesla’s advanced battery systems.