Tesla-approved adhesives provide superior performance and durability for vehicle repairs, with high heat and environmental resistance, ensuring long-lasting bonds through extreme conditions, from engine bay work to dent repairs, thus preserving car aesthetics and safety in both simple and intricate tasks.

Tesla-approved adhesives are revolutionizing industrial and automotive bonding, offering superior resistance to heat and environmental stress. This article explores how these specialized adhesives, designed to meet Tesla’s stringent standards, provide lasting solutions for demanding applications. From high-temperature endurance to protection against harsh weather conditions, Tesla-approved adhesives ensure structural integrity and extended product lifespans. Discover the key benefits and learn how these innovative materials are transforming industries.

- Tesla-Approved Adhesives: A Superior Choice

- Heat and Environmental Resistance: The Key Benefits

- Ensuring Longevity in Extreme Conditions

Tesla-Approved Adhesives: A Superior Choice

Tesla-Approved adhesives stand out as a superior choice for vehicle repairs and maintenance, especially when tackling challenging conditions like extreme heat or environmental stressors. These specialized adhesives are meticulously tested to meet Tesla’s stringent standards, ensuring they can withstand the demanding requirements of electric vehicles (EVs). By choosing Tesla-approved adhesives, auto body shops and vehicle owners alike benefit from enhanced durability and long-lasting performance.

This superior quality translates into a smoother and more reliable process for hail damage repair or any other intricate bodywork tasks in the vehicle body shop. Unlike conventional adhesives, those approved by Tesla offer excellent resistance to high temperatures and varying weather conditions, ensuring repairs hold firm even under extreme circumstances. Consequently, they become a go-to solution for professionals seeking to deliver top-notch results in both auto body shops and beyond.

Heat and Environmental Resistance: The Key Benefits

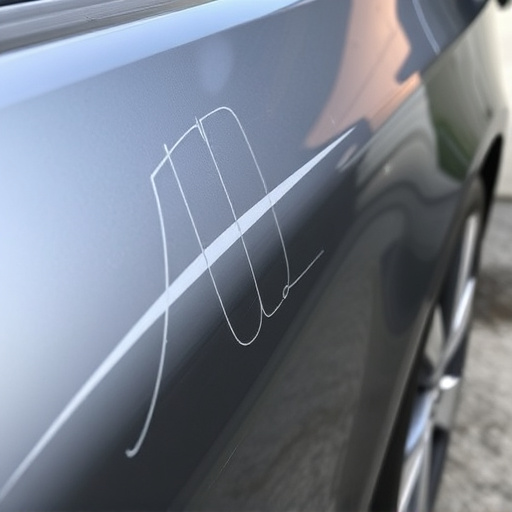

The primary advantage of Tesla-approved adhesives lies in their exceptional heat and environmental resistance. These specialized adhesives are designed to withstand extreme temperatures, making them ideal for automotive applications where exposure to high heats is common during driving and vehicle maintenance. Whether it’s adhering components within a car’s engine bay or repairing a car dent repair, these adhesives ensure long-lasting bonds that can resist the rigors of daily use and varying weather conditions.

Furthermore, their environmental resilience is particularly beneficial for auto body repair. In addition to resisting heat, these adhesives offer protection against moisture, UV radiation, and chemical exposure—all common challenges in maintaining a vehicle’s exterior. By utilizing Tesla-approved adhesives, car body repairs can not only be more durable but also better equipped to preserve the aesthetics and overall value of the vehicle over time.

Ensuring Longevity in Extreme Conditions

In the automotive industry, especially within the realm of Tesla-approved adhesives, ensuring longevity in extreme conditions is paramount. These specialized adhesives play a crucial role in maintaining structural integrity, particularly during challenging weather scenarios and post car collision repair. By adhering to Tesla’s stringent standards, these products offer superior resistance to heat and environmental factors, ensuring the durability of car body shop repairs.

This resilience is vital for preserving the aesthetics and safety of vehicles, whether it’s a simple fender repair or more intricate car collision repair work. The adhesives’ ability to withstand extreme temperatures and varying weather conditions makes them indispensable tools in modern car body shops, fostering long-lasting and reliable results.

Tesla-approved adhesives are a game-changer for industries facing harsh environmental challenges. These specialized bonding solutions offer exceptional heat and stress resistance, ensuring longevity in extreme conditions. By utilizing these advanced adhesives, manufacturers can achieve superior performance and durability, meeting the stringent requirements of Tesla and other tech leaders. This innovative approach to adhesion paves the way for revolutionary product designs and enhanced structural integrity in demanding sectors.