Tesla-approved adhesives are crucial for achieving structural integrity and aesthetic restoration in vehicle repairs, especially paintless dent repair. These specialized products cater to diverse needs, from high-strength formulas for structural bonds to cosmetic matches maintaining original specifications. They ensure superior quality and compatibility with Tesla vehicles but pose challenges like training costs, equipment investments, and higher material expenses. Proper application demands advanced techniques to maintain the vehicle's original quality and value.

Tesla-approved adhesives play a crucial role in both structural and cosmetic repairs, ensuring vehicles maintain their performance and aesthetic appeal. This article delves into the stringent adhesive standards set by Tesla, exploring the various types of adhesives approved for use. We’ll also discuss the benefits and challenges associated with these specialized products, highlighting why adhering to Tesla’s guidelines is integral for quality repairs.

- Understanding Tesla's Adhesive Standards

- Types of Tesla-Approved Adhesives for Repairs

- Benefits and Challenges in Using Approved Adhesives

Understanding Tesla's Adhesive Standards

Tesla has stringent standards when it comes to adhesives, especially for structural and cosmetic repairs on their vehicles. As a car body shop aiming to undertake Tesla repairs, understanding and adhering to these standards is paramount. Tesla-approved adhesives are not just about ensuring the vehicle’s safety; they also guarantee superior performance in both structural integrity and aesthetic restoration.

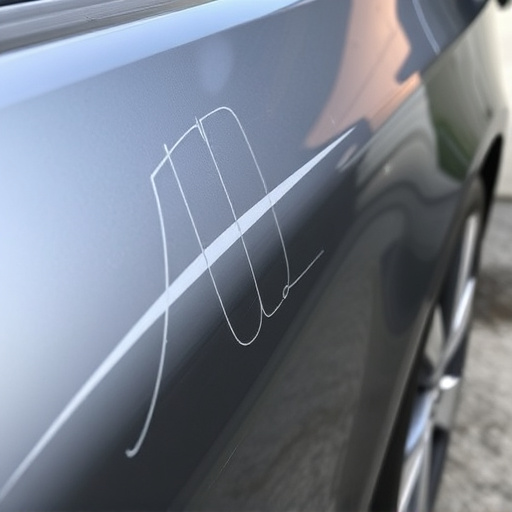

These adhesives play a crucial role in various repair processes, including paintless dent repair, which demands precision and minimal interference with the vehicle’s original finish. The use of approved adhesives ensures that repairs are long-lasting, compatible with Tesla’s advanced manufacturing techniques, and maintain the vehicle’s original look, making them essential for any skilled vehicle paint repair technician.

Types of Tesla-Approved Adhesives for Repairs

Tesla-approved adhesives come in various types, each designed for specific repair needs. For structural repairs, high-strength adhesives are used to ensure the integrity and stability of the vehicle’s components. These adhesives can withstand significant stress and pressure, making them ideal for reinforcing damaged or weakened structures.

When it comes to cosmetic repairs, such as those involving car restoration or vehicle paint repair at an auto collision center, Tesla-approved adhesives offer precise bonding capabilities. These adhesives are formulated to match the vehicle’s original specifications, ensuring seamless integration during the repair process. This not only maintains the aesthetic appeal of the car but also guarantees that all repairs meet Tesla’s stringent quality standards.

Benefits and Challenges in Using Approved Adhesives

Using Tesla-approved adhesives offers numerous benefits for both structural and cosmetic repairs. These specialized adhesives are designed to meet stringent quality standards set by Tesla, ensuring they provide superior bonding strength, durability, and compatibility with the company’s vehicles. They streamline the repair process, enabling efficient collision damage repair and tire services while maintaining the vehicle’s original aesthetics.

However, incorporating Tesla-approved adhesives also presents challenges. Auto repair near me shops must invest in training and equipment to handle these advanced materials effectively. The cost of approved adhesives can be higher compared to conventional options, adding a financial consideration for both businesses and consumers. Moreover, proper application requires precise techniques and expertise to avoid issues like poor adhesion, curing problems, or visible repairs, which can compromise the vehicle’s overall quality and value.

Tesla-approved adhesives play a pivotal role in ensuring both structural integrity and cosmetic excellence during repairs. By adhering to stringent standards, these specialized products offer benefits such as enhanced durability, superior bonding strength, and color consistency. However, challenges like cost and availability may arise, requiring automotive professionals to stay informed and committed to using only Tesla-approved materials for optimal results.